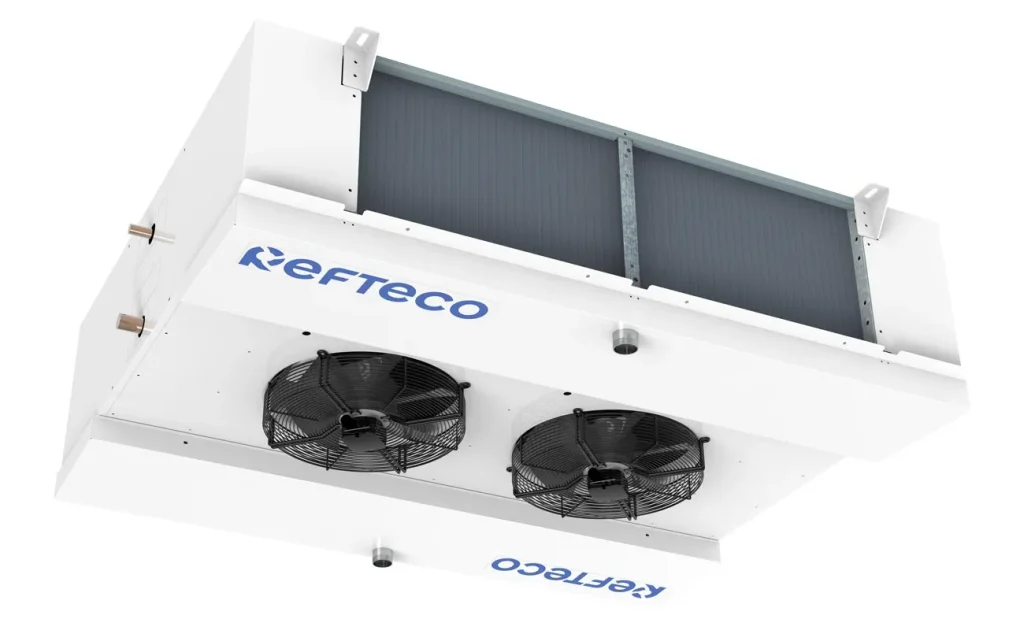

Evaporators cubic industrial RN

New series of industrial cubic evaporators for medium and large cold rooms with volume from 200 to 3100 m3.

This line of evaporators has been designed for particularly heavy-duty use for cooling and preserving fresh or frozen products with temperatures from -40 to +25°C.

The RN series of industrial evaporators, thanks to the wide range of standard models and accessories, satisfies any design and plant engineering requirement.

Direct expansion evaporators RNSE for HFC and HFO

Direct expansion evaporators RNSB for CO2

Pump evaporators RNLA for NH3

Application area

- Food & Beverage

- Logistic centers

- Air conditioning

Technical features

Evaporators available for refrigerant fluids HFC, HFO, CO2 and NH3.

Over 1890 models.

From 1 to 5 fans.

Cooling capacity

From 15 to 310 kW (SC2 conditions)

Fan-motors

Diameter 500 – 560 – 630 – 710 – 800 – 910 mm with aluminum blades and corrosion-resistant powder-coated grids.

External rotor fans with thermal contacts for effective protection. Fan conveyors with optimized fan profile ensure maximum fan efficiency, higher air throw and lower noise.

Fin spacing

4 – 6 – 7 – 8 – 10 – 12 mm

Casing

Casing in corrosion-resistant powder-coated aluminum or galvanized steel. Drip tray with welded corners and welded draining connection for a perfect seal. AISI 304 stainless steel screws.

Heat exchanger

Evaporators for CO2, HFC and HFO are equipped with 12 mm diameter copper tubes that ensure high heat exchange and low pressure drops.

Pump evaporators for NH3 are made with 16 mm diameter stainless steel pipes that ensure low pressure drops and heat exchanger connections on the same side.

The heat exchanger is made with thick fins that allow greater heat transfer, superior mechanical strength and long service life.

RNS evaporators, with staggered tube arrangement and optimized ratio of finned (secondary) surface to tubes (primary) surface, enabling high specific cooling capacities.

RNL evaporators, with squared tube arrangement and a high ratio of finned (secondary) surface to tubes surface (primary), ensures lower dehumidification and less defrost cycles.

Defrost

Hot glycol, electric, light electric, water, hot gas, combined defrost.

Options

Stainless steel tubes, stainless steel casing, stainless steel fins, Al/Mg fins, fans with stainless steel grids, coil coating, EC fans, ATEX fans, high pressure fans, shut-up, legs for floor installation, insulated drip tray, air streamer, inclined fans, collar for air distribution sock, fans wiring, fan ring heater, safety switches, insulated inlet hood, re-heating coil.

Related products

Alternatively you can call us

Monday to Friday

8:00 to 12:00

13:00 to 17:00

to the phone number:

or write to us directly, via email: