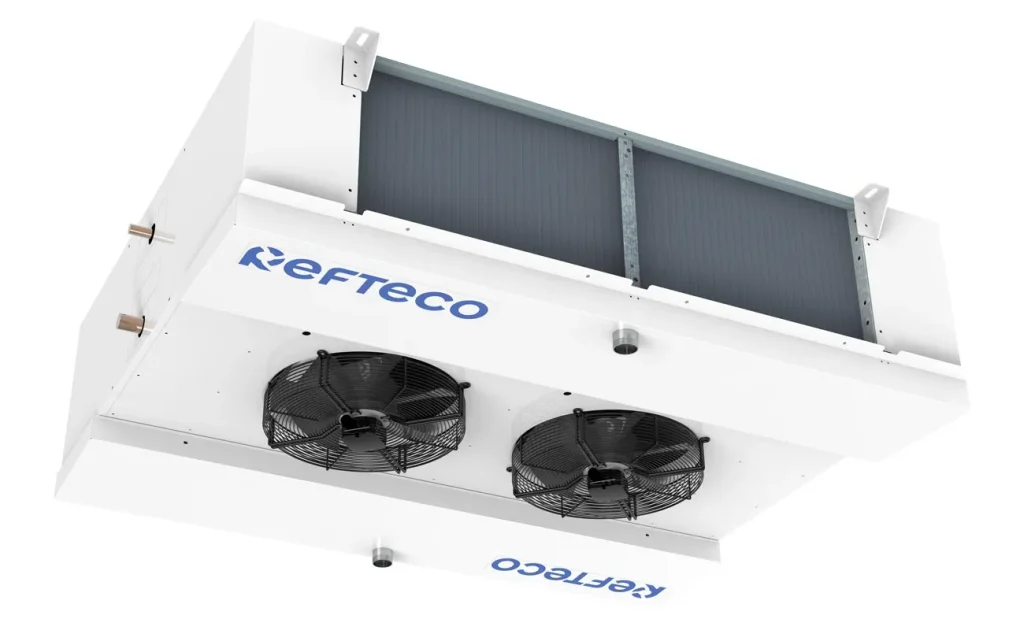

Evaporators shock freezer REBFT – RBBFT – RABFT

New line of shock freezers specifically designed for rapid cooling and freezing of meat, fish, ice cream and pre-cooked dishes in tunnels where high cooling capacity is required in limited spaces.

This range of shock freezers finds its best application in tunnels where the product is placed in trolleys, ensuring perfect cooling. This range of evaporators is equipped with fans that provide suitable static pressure to ensure fast and uniform cooling of the product. Installation and maintenance are extremely simple, thanks to the height-adjustable feet and easily removable cover panels.

Direct expansion evaporators REBFT for HFC and HFO

Direct expansion evaporators RBBFT for CO2

Pump evaporators RABFT for NH3

Application area

- Food & Beverage

Technical features

Evaporators available for refrigerant fluids HFC, HFO, CO2 and NH3.

90 models.

From 1 to 5 fans.

Cooling capacity

From 32 to 145 kW (SC2 conditions)

Fan-motors

Diameter 500 – 630 mm with aluminum blades and corrosion-resistant powder-coated grids.

External rotor fans with thermal contacts for effective protection.

Fin spacing

4 – 6 – 8 – 10 – 12 mm

Casing

Casing in corrosion-resistant powder-coated galvanized steel. Drip tray with welded corners and welded draining connection for perfect seal. AISI 304 stainless steel screws.

Heat exchanger

Evaporators for CO2, HFC and HFO are equipped with 12 mm diameter copper tubes that ensure high heat exchange and low pressure drops.

Pump evaporators for NH3 are made with 16 mm diameter stainless steel pipes that ensure low pressure drops and heat exchanger connections on the same side.

The heat exchanger is made with thick fins that allow greater heat transfer, superior mechanical strength and long service life.

The heat exchanger is equipped with a tube suspension system that avoids contact between the tubes and the frame, ensuring complete protection of the battery against vibrations and thermal expansion.

Defrost

Electric, hot gas, water, hot glycol.

Options

Heat exchanger with differentiate fin spacing, stainless steel tubes, stainless steel casing, stainless steel fins, Al/Mg fins, fans with stainless steel grids, coil coating, EC fans, ATEX fans, high pressure fans, insulated drip tray, fans wiring, fan ring heater, safety switches.

Prodotti correlati

Alternatively you can call us

Monday to Friday

8:00 to 12:00

13:00 to 17:00

to the phone number:

or write to us directly, via email: